The Maxit mortar pad

The new mortar System: The evolution to Brickwork 3.0

Available from JUWO

Videos and all informations here

Quick, easy and reliable: the "maxit mortar pad"

The technical demands made on a modern building envelope are increasing constantly. It is becoming more and more difficult to keep up with these demands in on-site handling. As a result, the actual bricklaying process has a crucial role to play in the creation of permanent and highly heat-insulating brickwork. Franken Maxit's new maxit mortar pad minimizes sources of error while accelerating and simplifying the necessary procedures. With it, the traditional procedure using a covering of thin-bed mortar enters the next stage of evolution.

Values within ensure quality on the outside

Mortar pads are industrially prefabricated mortar panels which are subjected to quality checks before leaving the factory. They consist of light thin-bed mortar and a water-soluble hot-melt adhesive. An integrated fibre glass reinforcement ensures additional stability.

Mortar pads are used on planed brickwork, where they are simply laid onto the stones or bricks. Just add water and the hot-melt adhesive sets hydraulically to form a thin, full-surface mortar joint with a thickness of one to three millimetres. This setting process is similar to that for conventional mineral mortar, so it ultimately achieves comparable structural engineering values.

In terms of their stability and bonding properties, therefore, mortar pads are comparable with a thin-bed mortar of class M10. In addition, the maxit mortar pad is a mineral product made from natural raw materials. This makes it easy to erect a purely mineral outer wall (mortar, stone, plaster).

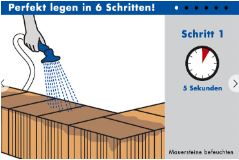

Moisten blocks

Lay on Maxit mortar pads

Cut and adjust Maxit mortar pads if necessary

Moisten Maxit mortar pads

Lay blocks with full surface

Align blocks in usual way

The handlinf step by step and animated on the Maxit Website here